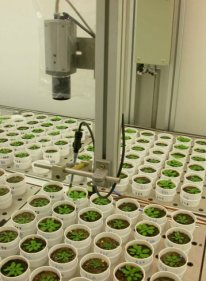

The Phenopsis phenotyping automaton, intended for agronomic research, is an automated system for irrigation, image capture and storage, weighing and various controls of more than 500 potted plants individual.

Ce système équipe déjà le laboratoire LEPSE (INRAe de Montpellier) en trois exemplaires, l’INRAe de Toulouse, et le laboratoire Bayer CropScience. Un site est dédié aux résultats obtenus grâce à Phenopsis.

Phenopsis is a mechanically very robust system, designed to operate for years in a humid environment.

For your needs in high throughput phenotyping, Optimalog offers you the supply of Phenopsis in standard version or with specific variants studied on specifications. The experience acquired since the installation of Phenopsis 1 (2003) makes Optimalog a specialist in the technical aspects of phenotyping and its automation, guaranteeing rapid installation of your equipment and the success of your project.

The photo below shows one of the systems as a whole, before the doors of the climatic chamber were installed.

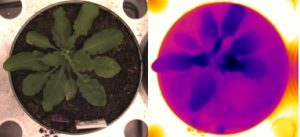

Automated image capture with digital cameras

The shots are taken in visible light or in infrared light. Images are stored locally and can be automatically sent to a server.

Control of the evolution of each plant

A precision electronic balance weighs each pot at the frequency determined in the experiment. The collated results are stored locally and can be injected automatically in real time into an SQL database.

Irrigation is carried out according to the weighing result in order to obtain precise dosages. It is possible to have one or more pumps, the selection of the pump is made individually for each pot.

Control and supervision PC :

The PLC is entirely managed by a standard PC, using the automation software Optima PLC .

A user-friendly and intuitive interface makes it easy to define the parameters of the experiments and to follow their progress.

The experimenter defines the times at which the cycles are launched. For each cycle, he can choose the actions to be performed: weighing, irrigation, visible or infrared photo taking. He can also define, for each pot, if it must be checked, the target weight (pot + plant), the irrigation pump to activate, etc.

In the event of a hazard, the system informs the experimenter by sending an email or an SMS alert.

External control of the system, via the Internet, can be easily set up, and allows monitoring of the experiments in progress from the experimenters' homes, as well as remote maintenance by Optimalog.

Features :

Standard dimensions (W x L x H): 1500 x 4600 x 2000 mm

Control and supervision: Industrial PC or Standard PC with Windows XP PRO or Vista operating system, and Optima PLC software.

Standard power supply: single phase 230V 50Hz